Page 18 - Summer 2018 GMC Vintage RVing

P. 18

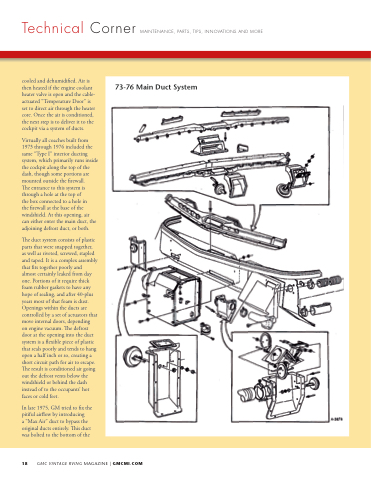

Technical Corner MAINTENANCE, PARTS, TIPS, INNOVATIONS AND MOREcooled and dehumidified. Air is then heated if the engine coolant heater valve is open and the cable- actuated “Temperature Door” is set to direct air through the heater core. Once the air is conditioned, the next step is to deliver it to the cockpit via a system of ducts.Virtually all coaches built from 1973 through 1976 included the same “Type I” interior ducting system, which primarily runs inside the cockpit along the top of the dash, though some portions are mounted outside the firewall.The entrance to this system is through a hole at the top ofthe box connected to a hole inthe firewall at the base of the windshield. At this opening, air can either enter the main duct, the adjoining defrost duct, or both.The duct system consists of plastic parts that were snapped together, as well as riveted, screwed, stapled and taped. It is a complex assembly that fits together poorly and almost certainly leaked from day one. Portions of it require thick foam rubber gaskets to have any hope of sealing, and after 40-plus years most of that foam is dust. Openings within the ducts are controlled by a set of actuators that move internal doors, dependingon engine vacuum. The defrost door at the opening into the duct system is a flexible piece of plastic that seals poorly and tends to hang open a half inch or so, creating a short circuit path for air to escape. The result is conditioned air going out the defrost vents below the windshield or behind the dash instead of to the occupants’ hot faces or cold feet.In late 1975, GM tried to fix the pitiful airflow by introducinga “Max Air” duct to bypass the original ducts entirely. This duct was bolted to the bottom of the73-76 Main Duct System18 GMC VINTAGE RVING MAGAZINE | GMCMI.COM