GMC Motorhome History

William Bryant | Enthusiast

Biography | Born and raised in the Hudson Valley of New York State, he graduated from the State University of New York at Morrisville, NY. He served in the Army in the Marshall Islands during the Korean War and then went to work at the IBM Corporation for the next 37 years. Retirement has allowed Bill and his wife Nita to travel extensively by RV as well as enjoying his hobby of antique automobiles. His lifelong interest in automotive history sparked his amassing a collection of GMC Motorhome history and artifacts. The GMC Motorhome was manufactured at Pontiac, Michigan from 1973 through 1978.

Location | Pleasant Valley, NY

Written by William Bryant

In the late 1960’s and early 1970’s it was evident that a market for motorized RVs was increasing dramatically. It appeared it might be a market worth pursuing. The motorized RV market at that time consisted of truck chassis supplied to about 50 different coach builders, each manufacturing their version of what they thought a motorhome should be.

A unique vehicle using a front wheel drive power plant from the Olds Toronado and a unique tandem rear wheel suspension using a hydro-pneumatic spring was proposed.

Evaluations of a vehicle using this unique rear suspension got underway at the GM Tech Center in Warren, MI. Specifications of many competing motor homes were scrutinized, floor plans were evaluated and initially it was decided to proceed with 20-foot and 24-foot motor home designs. Layout drawings of numerous floor plans under evaluation lined the GM Tech Center walls. A full scale plywood (fiberboard) seating buck was built for evaluation of different interior plans in the Tech Center basement. Much of the interior design was done by GM employees from the Frigidaire Division

The first vehicle built to demonstrate these unique designs was assembled using tandem wheels at the rear supported by the unique hydro-air spring from the Saginaw Division of GM. A power steering pump was used for hydraulic pressure for this suspension system. The engine and drive train used the Olds Toronado front wheel drive with the 455 cu. in. engine, 425 Hydramatic transmission and the 3.07 differential from the Toronado trailer towing option. This design allowed for a low profile and low center of gravity, with attendant handling and ride improvements as compared to a truck chassis. The front section of the frame made use of the Toronado design and bolted up to the center section “C” channel side rails. A modified van body built by Union City Body Co, Union City, IN was mounted on this frame.

This development mule was called the “pie wagon” by those working on the project. Windows and bus seats were installed and sand bags were strategically placed inside to represent the weight of an equipped motor home. Full fender skirts covered the wheels to hide the unique suspension from spy photographers who often took pictures of vehicles being tested at the GM Proving Grounds. The primary purpose of this vehicle was to demonstrate to GM management the much superior handling and ride in comparison to the truck chassis normally used for motor homes. It is reported that GM management was favorably impressed and the project was given approval to proceed with further development.

The engineers and designers responsible for the development of the GMC Motor Home were; Martin J. Caserio, General Motors VP and GMC Truck and Coach General Manager, in 1973 his replacement was Alex C. Mair, Kurt Stubenvoll was responsible for motor home Product Development, Ralph Merkle was the engineer in charge of chassis development and John Locklin had engineering responsibility for the motor home body. Nancy Bundra started as the secretary to Kurt Stubenvoll and advanced to the engineer in charge of Interiors, AC & Heating. Michael Lathers from the Design Center was responsible for the motor homes styling. Many other talented engineers contributed to what was to become a classic as well.

Industry rumors had been circulating for some time that GM was going to be building a motor home. On February 7, 1972 it was made official. The national press reported that GM was to “play a role in the motor home market.” By this time the GMC Motor Home lengths had been identified as 23-foot and 26-foot. The increase in length was the result of additional interior content that designers and sales felt was necessary for a well equipped motor home. Prices were reported to be between $12,000-16,000.

About this time the new vehicle was known as the TVS-4, Travel Vehicle Streamlined. Part of the reason this vehicle is so different from other motor homes of the era is that it was not conceived as just a “camper,” but as a vehicle for comfortable travel as well. Slogans used later in the GMC Motor Home advertisements demonstrated this, for example: “It doesn’t ride like a truck, it doesn’t look like a box,” “Our goal was to make getting there as much fun as being there”, “It’s as easy to live with on the road as it is standing still”, and “The show place that goes places.” All of these slogans placed great emphasis on the traveling aspects of motor homing and not just how it functioned while parked at the campsite.

The Motor Home design continued to evolve in the two main areas of styling and chassis. The Design Center was continuing with both the external and interior designs. There were twelve designers working with sketches and 1/8 scale (A-scale) clay models. Three or four of these 1/8 scale clay models were made, each with unique design characteristics, each refining their shapes closer to the final form . Once these models were completed, evaluated and approved, full sized drawings were made using ¼ inch tape to outline the front, rear and side design. These drawings would guide the designers in the next stage: a full size clay model.

An important part in developing the shape of this motor home was to determine just how efficient it would be moving through the air. A 1/16th scale model was built for the purpose of determining the coefficient of drag, Cd. Test time was purchased at the Guggenheim wind tunnel facility in California, the testing indicated a Cd of .310.

The clay full scale 26-foot motor home was likely the largest clay model GM ever made. Once the shape was completed, the clay surface was “polished” with a sponge and cold water and finished with a silver-blue film of Di-Noc, replicating the painted surface of a vehicle.

Upon completion of the full scale clay, plaster cast segments were made of it. Dimensional drawings were made of this final design for tooling and early prototype fiberglass parts for the first prototype bodies

Pictures of the scale models, the sketches and drawings and finally full size clay are most interesting. The evolution from the earliest designs with pronounced fender flares, wrap around rear windows and tail lights and other eye pleasing shapes, drifted toward a still pleasing, but more “manufactureable at reasonable cost” design in the end.

House and Garden was used as a consultant for the interior décor and exterior colors. They were a recognized authority on the colors and designs of that era. Ed Cole, GM President, suggested bright colors should be used. One story that has been confirmed by several people, report that at a meeting where these details were being discussed, Ed Cole pointed to the tie of Chief Engineer Wally Edwards and said, “one of the colors should be like Wally’s tie.” It was a tie with orange stripes, an orange color (bittersweet) was offered in 1973 and 1974, and Wally still has that tie.

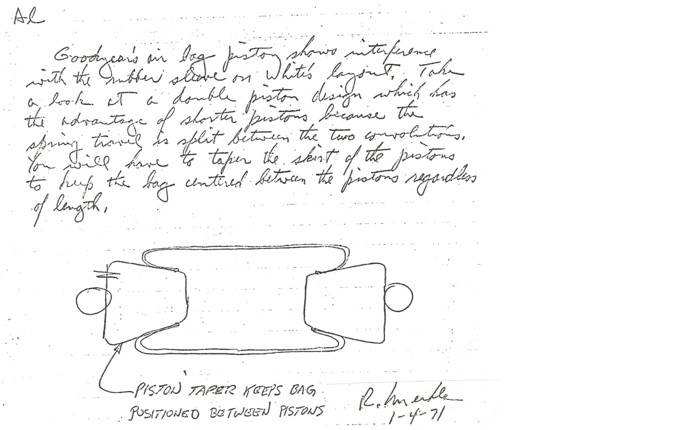

The chassis design was continuing as well. The engine and drive train layout was progressing rapidly since it required a few minor changes to the existing Olds Toronado design. The tandem rear wheel hydro-air rear suspension had been the key design element for this vehicle. It allowed for the low floor as well as a measured improvement in ride and handling. Less intrusion into the living area than dual wheels would have caused was a feature as well. Tooling costs for the hydro-air design had come in much higher than anticipated. A less costly design was requested as a backup and work began on a replacement.

A full air spring was designed. The first prototype spring was delivered by Firestone March 1971 and became the production air spring with only minor modifications, a slightly larger diameter and slightly shorter in length.

In the Experimental Engineering area five pre-test chassis were being built. The pre-test bodies would later be installed on four of them. The fifth chassis would be used for pictures and display. The completed units would be used for various purposes, some for test, some for pictures and some for shows. We will hear more about these later.

John Locklin, the body engineer, was spending most of his time at G.L. Bowen & Co. the job shop that was supplying the draftsmen in documenting the motor home body. Measurements of the plaster casts made from the full size clay were translated into drawings to be used to make the dies, body structure and skin. Locklin’s background as an Aeronautical Engineer was showing up in many of the design features. The light weight of the aluminum and fiberglass body skin, the all aluminum body framing and the bonding of body panels with adhesives instead of rivets and screws. An important design feature also was the use of flat aluminum panels for body surfaces above the belt molding, including the roof. No body stampings were required, thus minimizing tooling and fabrication costs.

The large body dies required for the SMC (sheet molded compound) “fiberglass” panels were in place at the vendor, Engineered Molding Systems of Lancaster, Ohio. Lumps of SMC “dough” were strategically placed in the molds, with heat and pressure it took twelve minutes to process each panel.

At GMC, the first hardware that we would recognize as a GMC Motor Home was being assembled. The chassis with the Toronado front wheel drive assembly was pretty well defined. The rear suspension was still the tandem wheel Hydro-air suspension and many parts were still passenger car parts, such as the 5 bolt wheels and hubs. At the rear of the body, the large removable back panel had not yet been implemented.

GMC had decided to vendor out the interior up fitting PRF Industries was owned by Peter R. Fink, the builder of Travco and Sightseer motor homes. A new PRF division was formed to build the GMC interiors, Gemini Corporation, Mt. Clemens, MI. The Gemini facility designed and built all of the furniture; assembled all the modules; applied the Texolite laminate; and installed everything, bringing it all through the motorhome rear access opening. A number of start-up concerns had to be resolved. The complexity of fifteen different floor plans and the many available options contributed to a complicated interior assembly process as well. Approvals of the many different State as well as the many federal requirements had to be reviewed and met also.

With the prototypes now being assembled, their purposes defined, their activities would begin. The first public showing would be at Transpo 72, The U.S. International Transportation Exposition near Washington, DC (Dulles) from May 27 through June 4, 1972. Martin J. Caserio, General Motors vice president and general manager of GMC Truck & Coach, said the motor home prototype is representative of GMC’s long-term development program for a new chassis and body adaptable to a variety of purposes. “The 26-foot motor home to be exhibited at Transpo is the first application of the new GMC chassis and body design,” he reported.

(l to r) K. Stubenvoll, R. Stelter, M. Caserio, W. Edwards, B. Wilton

(l to r) K. Stubenvoll, R. Stelter, M. Caserio, W. Edwards, B. Wilton

Caserio said development work is continuing for other potential applications, such as a small bus for metropolitan transit operations, an ambulance and rescue vehicle, a mobile medical clinic, a vehicle for physically-handicapped riders, an airport bus and a display or service van. Many GM cars and trucks were on display there as well as the tan colored 26-foot Motor Home. The exterior was rather plain with no stripes or trim. In a brochure it was described as “An experimental prototype of GMC Truck & Coach Division’s complete motor home, to be marketed in early 1973″. The GM display was still labeled as a ‘Multi Purpose Vehicle” although all efforts were now focused on developing and producing a Motor Home.

Other motorhome prototypes were undergoing testing. A 23-foot Motor Home model named “Cape Cod” was at bench test. A computerized shake test installation, designed initially for trucks, permitted a seven-month series of critical component and total vehicle analyses. These tests otherwise would have required years to duplicate by using only conventional road testing. The programmed testing replicated Belgian blocks (cobble stones) cycled the suspension with hydraulic rams. Door latches were slammed, windshield wipers were cycled, and brake pedals were pumped all through a determined number of test cycles.

Coaches were tested as well for what seemed like endless hours at the Milford, MI, GM Proving Grounds. A modified passenger vehicle test was the criteria used, Proving grounds roads for 25,000 miles (regular durability), and 5,000 miles of Belgian blocks (accelerated durability).

Plans for the manufacture of the motor home were moving along rapidly. Plant #3 in Pontiac, MI had been outfitted with equipment and tooling. This was one of GMs older plants and it had a split-level floor plan. At the lower level, the chassis frame was collecting various sub assemblies as it proceeded down the line, front and rear suspension, tanks, air lines, electrical wiring and finally the engine and drive train. The upper level of the plant was used for body assembly. Individual aluminum pieces of the body’s frame were placed in manufacturing jigs which assembled and aligned them; they were then welded together as a unit. Aluminum and fiberglass exterior body panels were fastened to this frame with a 3M adhesive. This assembled body was then cleaned, prepped and painted. When completed, the body was lowered to the main floor where it was mated with the assembled chassis.

The first few motor homes moved slowly down the assembly line during the fourth quarter of 1972 and by the second week of November the first two dozen motor homes had been built. The first 100 were finished before the end of January 1973. In March, Alex Mair, General Manager of GMC Truck & Coach reported, “The initial response has surpassed even our most optimistic expectations.” Over 1,750 orders were received through mid-February. By June 1973 it was reported backorders totaled 3,000 units, and the current rate of motor home production was now nearly 20 units per day.

As might be expected, there were some start up problems. A new team-assembly concept at the GMC Pontiac, MI plant used a three member team assembling and the chassis and a six member team responsible for body and trim up fitting. This team-assembly concept was supposed to be the latest- greatest idea from Sweden. Both GMC management and the union had hopes that this team-assembly trial would help to reduce the repetitive work causing “worker blues.” The team concept didn’t meet expectations, lasted only a month or two, production then reverted to the standard “Detroit” auto assembly method.

By June 1973 GMC had 64 dealers signed up to sell and service GMC Motor Homes. The company had hoped to have 200 dealers by the end of 1973, but decided not to sign up any more until an adequate supply was available. GMC Motor Home dealerships were separate stand alone facilities, GMC Truck dealerships didn’t automatically become GMC Motor Home dealers. A minimum of three acres of buildings and land area solely for motor home operations was required. The cost for a GMC Motor Home dealership is reported to have been $250,000.

On January 3rd, 1973 at Anaheim Stadium in California, the GMC Motor Home was introduced to the news media representatives. Over 100 newsmen and women watched a demonstration of the vehicle’s performance capabilities; rode and drove the motor home themselves, and participated in a news conference with top GMC executives. News articles across the country said things like, “GM Motor Home to set industry on its ear,” “”GM has built the proverbial better mousetrap,” “If any product seems destined for success, it would appear to be the GMC unit,” “GM’s new motor home scores high in demonstrations,” … and many, many more.

Newsweek magazine stated, “GM’s new models reflect a grasp of problems that increasingly trouble consumers. For example, GM has engineered a number of safety features into its motor home that may well someday become government standards before long. It is also introducing a customer-service operation far ahead of any the free-wheeling business has so far known …” This emergency service provided a toll free number and immediately advised the owner of the nearest GMC Motor Home representative available for assistance on a 24 hour basis.

Alex Mair said that GMC could produce 8,000 unit’s a year with the current facilities on a one shift basis. He noted also the pricing of the new motor home placed it at about midway in the senior motor home market, which was identified as Class A motor homes selling for $9,000 and up. It was mentioned that GMC “hoped” to get 10% of the senior motor home market. Initial customer deliveries were to start in February.

The 1973 GMC Motor Home was available with a choice of four different models, six exterior colors, fifteen different floor plans, two different body lengths, and then there was the long list of available options! The first series of motor homes were named for National Parks; Canyon Lands, Glacier, Painted Desert and Sequoia. The 26-foot and 23-foot models both used the same model names. Three of the exterior colors were standard, White, Camel and Pineapple Yellow. Three were optional for an additional $34.00, Bittersweet (orange), Sky Blue and Parrot Green.

The total of fifteen floor plans were split between the two body lengths, eleven for the 26-foot coach and four for the 23-foot. Any one of the floor plans was available in any of the four models. The model names defined the interior décor, colors and upholstery patterns and NOT the floor plan.

Manufacturer’s suggested retail (base) price was $14,569.06 for the 26-foot and $13,569.06 for the 23-foot Motor Home.

A number of static RV shows and dynamic demonstrations were used in many. One of the most impressive demonstrations was of a GMC Motor Home followed by another brand of motor home fitted with a cover to obscure its manufacture (it was a Banner), running over ~3 inch x 4 inch type timbers spaced a few feet apart demonstrating the difference in suspension abilities. The GMC handled the timbers with ease; its tires danced over the obstacles with the body barely bouncing. The covered motor home with leaf spring suspension on a competitors chassis had the tires leaving the ground and appeared to be leaping in the air after the third or fourth timber was crossed. The viewing crowd loved it. Alex Birch, foreman of the Experimental Engineering shop, was the driver of the GMC in many of these demonstrations.

Starting in 1973 and continuing through 1977 a number of films were produced to promote the GMC Motor Home. Upon entering a dealership showroom, you might see what looked like a small screen TV set along with a number of film cassettes. GM called these units Mini-Theaters and films could be viewed with this self contained unit allowing the potential customer to view the many features of the GMC Motor Home. There are thirteen of these sales films, in addition there are three others from a TV program of the time that emphasized the joys of RV travel, Holiday on Wheels. There are also several service films intended to instruct service personnel with the proper repair procedures for various motor home sub-assemblies.

1973 Build Total = 2059

In late 1973, the 1974 models were introduced with little fanfare. They were a continuation of the previous models, incorporating running changes made to correct deficiencies in the early designs.

The GMC plant was operating at one shift while the Gemini plant was at two shifts. The Motor Home’s body and chassis were being assembled more rapidly than the interior up fitting at Gemini.

GMC Motor Home assembly operations were shut down in early December 1973, the official reason was stated as “to bring inventories in line with retail sales.” What started out at the beginning of the year as a great opportunity in a new market that at the time appeared almost limitless, suddenly had come to a screeching halt. The gasoline shortage had begun to seriously affect the RV industry.

At Las Vegas January 30-31, 1974, GMC announced a new series of vehicles for commercial, medical, and general transportation purposes and nine TransMode concept vehicles were shown to the press. Eleganza SE “featuring customized interiors much more luxurious than those in current models” were displayed as well. This was the start of Alex Mair’s plan to make the GMC Motor Home the “Cadillac of motor homes.” He had made the comment at one point that the GMC Motor Home was to GMC what the Corvette was to Chevrolet, its halo vehicle.

GMC management had given Alex Mair 90 days to develop a new upscale model in time for the Las Vegas show. The designers used an existing Oldsmobile upholstery fabric and Flexsteel seating for the first time. New colors and trim helped to make the Eleganza SE an attractive, unique coach. The designers had ordered enough material to make 50 SE coaches should the Las Vegas show result in dealers orders. It was a sell out at the show, the dealers liked the new model and the Eleganza SE production was on its way.

The Motor home Engineering Department was hard at work developing and evaluating changes and improvements for the up-coming 1975 model year production:

1974 Build Total: 1664

The 1975 model year indeed brought many changes to the GMC MotorHome. New model names were announced; Eleganza II and Palm Beach replacing the previous 1973-4 models. New, better quality Collins and Aikman automotive type woven fabrics replaced the previous printed fabrics used. Flexsteel seating with steel-welded frames and no-sag springs replaced the earlier furniture. Assembly of interiors at Gemini was discontinued and all of the interior up fitting was brought in house at another Pontiac, Michigan plant. Grand Rapids Furniture Co. was now building the interior modules, and dovetail joints replaced glue and staples.

Furniture Module Installation

Furniture Module Installation

The TransMode, an “empty motorhome,” advertised as “The Mobile Anything” for those who wanted to build their own interiors was available from 1975 through 1978. GMC no longer offered the 23-foot unit as a MotorHome, it was available only as a TransMode to be up fitted by others.

Many companies were up fitting the new TransMode as both motorhomes and for commercial applications. Some of the motorhome upfitters were Avion, Coachmen, Carriage, LRP, Midas, Norris, Hughes, Landau, Roll-a-long, El Dorado, Foretravel, Winnebago, plus a few others with very low build quantities.

TransMode upfitters for commercial purposes were many, a few of the vehicle uses were: Ambulances/emergency vehicles, bookmobiles, mobile ATM/Banks, airport shuttle buses, mobile showrooms, mobile radio stations, hearses, courtesy coaches for beer and soda distributors, as well as many more.

1975 Build Total = 1656

The 1976 GMC MotorHome models arrived with few changes from the previous year. Two new models were introduced in addition to the Eleganza II and Palm Beach carryovers, the Glenbrook and Edgemont. The Edgemont (twin bed/dry bath) was the price leader with a base price about $1000 below the other three models

This model year, GMC MotorHome production reached its peak production build volume.

1976 Build Total = 3260

The 1977 Kingsley was a new model with the Eleganza II and Palm Beach continuing to be offered. The Kingsley replaced the previous years Glenbrook, and the Edgemont was replaced by a new twin bed/dry bath floor plan in the Eleganza II.

Another model, the Coca Cola was built in two versions, the “standard” one in Cameo white with a red horizontal stripe the same pattern as other GMC Motorhomes . The second Coca Cola model was the GadAbout, this one had all the bells and whistles. The exterior paint was Cameo white with a sweeping wedge of Coca Cola red up the coach sides blending to a yellow near the top rear of the coach. The “GadAbout” name appeared near the front and a bottle cap shaped spare tire cover was at the rear. Inside, the Coca Cola red upholstery was the same in both coaches. The refrigerator door graphics made it look like a soda vending machine! Other extras were, a “Coca Cola” entry floor mat, clock, mirrored picture, rear table with a “Coke” checker board pattern and on the dash above the glove box was an attractive pewter plaque with a GadAbout motorhome in profile and the slogan,” Coke adds life to…cruisin in a GadAbout.” Five GadAbouts were given away to five first prize winners of a Coca Cola contest held December 1977. Twenty five second prize winners each received the use of a GMC Motorhome for two weeks along with $3,000 in cash. The GMC records indicate a total of 55 Coca Cola models were built, most in 1977 and a couple in 1978

The 455ci engine was replaced with the 403ci engine by the end of January 1977 and was used for all remaining motorhome production. GM’s downsizing had started and would soon have severe implications for the GMC Motorhome.

On November 11, 1977 Robert W. Truxell, General Manager of GMC Truck and Coach announced the phase out of GMC MotorHome and TransMode production.

1977 Build Total = 2403

The 1978 model year began with three models of GMC MotorHome interiors, Eleganza II, Palm Beach and Kingsley. The TransMode continued with many upfitters participating. The major upfitter since 1975 was Coachmen Industries (Jimmy Motors) producing the Royale (26-foot) and Birchaven (23-foot).

MotorHome and TransMode production finally ended July 1978.

1978 Build Total = 1879

Total Production for 1973-1978 = 12,921

Phase Out

A press release datelined Pontiac, Nov.11, 1977 read as follows: “GMC Truck & Coach Division of General Motors plans to discontinue producing luxury MotorHomes and similar TransMode multi-purpose vehicles and convert those plant facilities to expand truck operations, a GM vice president said today. Robert W. Truxell, general manager of GMC Truck & Coach said, “As a result of this action, GMC will be able to utilize production facilities more effectively for servicing growing truck demands.”